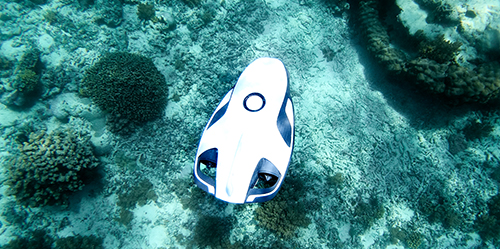

To demonstrate how a structural testing strategy is applied in practice, consider a newly developed subsea drone intended for surveillance and data collection at significant depths. Structural testing is integrated early in the design cycle, during validation and refinement, to assess performance under real-world conditions across varied mission durations.

Mission Context

A development team is tasked with validating a new subsea drone engineered for long-duration surveillance missions at depths of up to 14,000 feet. On paper, the structural requirements are:

- Survive pressures exceeding 6,000 psi

- Operate in temperatures as low as 33°F

- Endure months of immersion in corrosive saltwater

Testing Approach

Rather than jump into a full-system validation, the engineers begin with a simulation. Using finite element models, they predict which components are most likely to fail: a polymer-sealed battery housing and a dissimilar-metal joint in the propulsion assembly. These areas become the first to undergo physical testing. By isolating them early, the team avoids wasting time and resources reworking the full system if problems emerge.

During a combined pressure and temperature test, the battery housing leaks intermittently, and only during thermal cycling. The team redesigns the seal geometry and reruns the test. This time, it passes. Then, the rest of the structure is subjected to a high-speed cyclic pressure test, simulating repeated descents and ascents. Embedded sensors track internal pressure and strain in real time, helping the team confirm that the updated components perform acceptably. They simulate the full mission lifecycle in less time, using accelerated life testing to surface failures that wouldn’t show up in a single dive.

By the time final qualification testing begins, the team isn’t guessing. They’ve already adapted the design in response to test data, refined their measurement strategy, and proven that the drone can survive the most extreme parts of its mission profile.

Structural Testing as a Strategic Advantage

When engineering teams approach it strategically, structural testing becomes a powerful tool to accelerate time to market and improve product reliability. But it’s also one of the most underestimated phases of product development. Teams assume testing will be fast, that the first design will pass, or that in-house resources are sufficient only to encounter unexpected failures, delays, or data gaps.

Working with a structural testing specialist helps avoid those pitfalls. Experienced partners bring equipment, like Stress Aerospace and Defense’s high-pressure vessels with pass-through monitoring, and the foresight to design effective test programs, integrate instrumentation correctly, and avoid costly oversights. If a test is not executed properly or produces bad data, the entire testing process may need to start over, including the creation of new test articles, which can cause extensive delays to a product launch. They understand how to balance fidelity, feasibility, and speed, whether you need early proof-of-concept stress testing or formal qualification for defense procurement.

In complex programs where standards may not exist yet, detailed reporting of test setups, sensor configurations, and observed results creates clarity and confidence for all stakeholders. Testing isn’t just about finding out whether a product fails—it’s about understanding how, when, and why it might, so the right design decisions can be made early.