Innovative Design | Reliable Analysis | Precision Testing

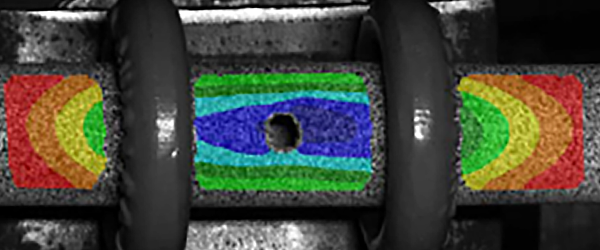

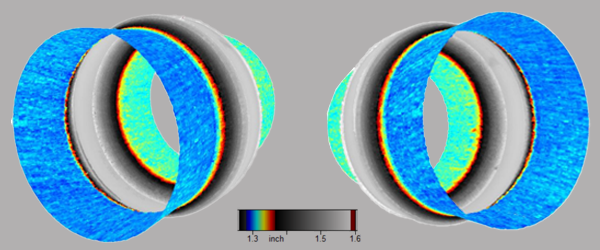

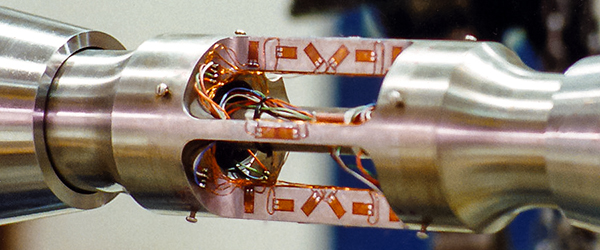

When a private space company needed to test the strength and flexibility of rocket engine ducts carrying cryogenic fuel and oxidizer, they turned to Stress Aerospace & Defense. Using a custom-built Stewart Table (Hexapod), our engineers performed six-degrees-of-freedom (6DOF) testing to simulate real-world launch conditions. The goal: determine structural limits under peak loading and gather critical stiffness data.

This highly technical project demanded innovation, rapid adaptation, and a deep understanding of complex hydraulic systems. Our team not only delivered but enhanced the test rig mid-project to meet rising performance demands—completing all testing successfully.