Product development and manufacturing success often rely on thorough testing methods that produce meaningful information about a product’s capabilities and limitations. For products in cyclic pressure applications, pressure cycle testing can be very important, expediting the qualification process and simulating years of service conditions in a condensed timeframe. This article explores the role of pressure cycle testing across industries and its numerous benefits.

What is Pressure Cycle Testing

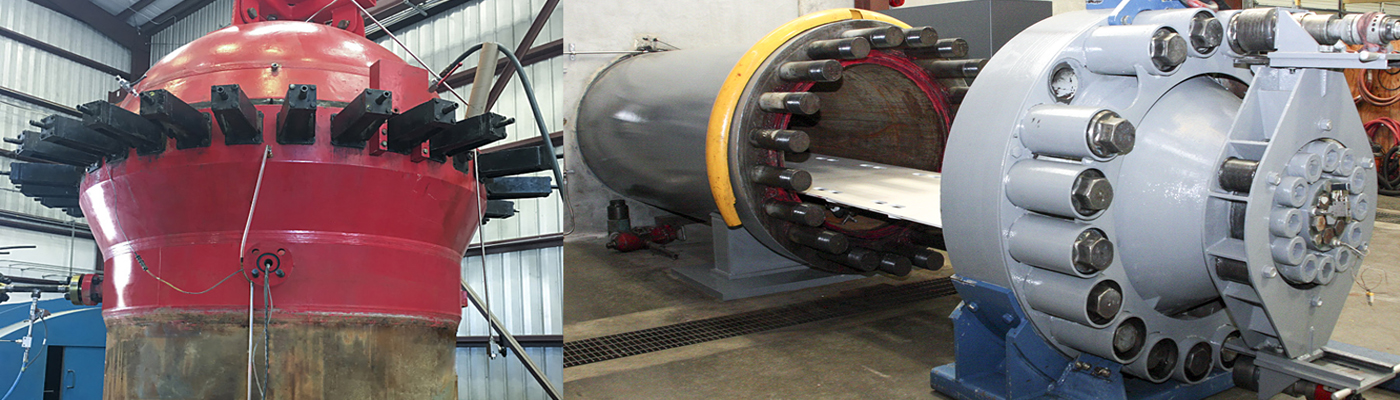

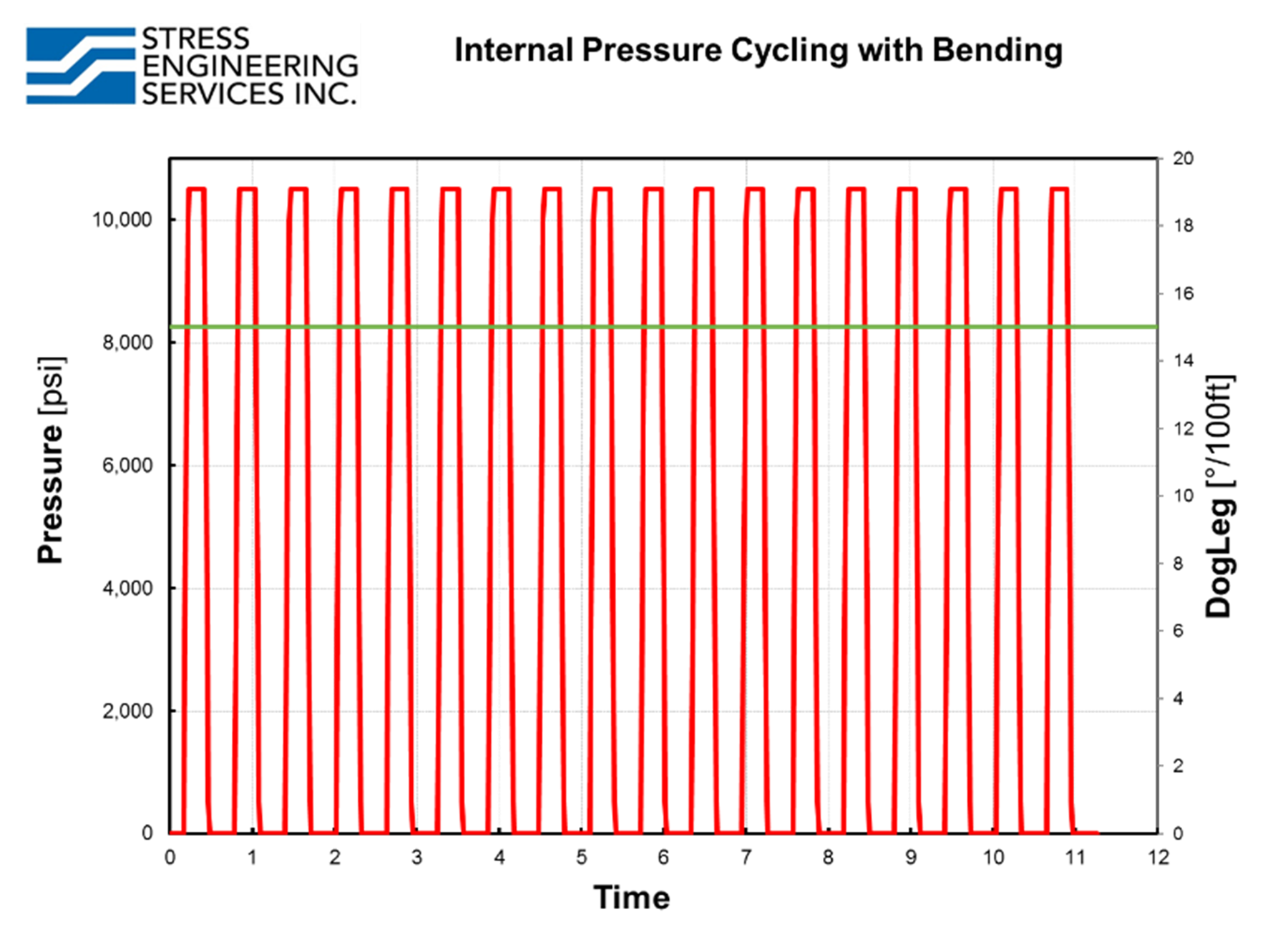

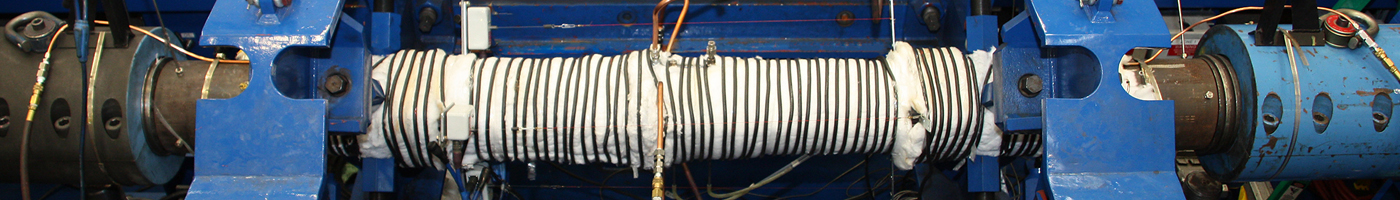

Pressure cycle testing exposes a product or component to cyclical pressure loads, effectively simulating real-world scenarios in sectors such as medical devices, aerospace, industrial control systems, energy, and automotive parts. Stress Aerospace and Defense conducts comprehensive testing programs demonstrating the adaptability of pressure cycle testing, encompassing parameters like sine and square wave pressure profiles, pressures up to 30,000 psi, frequency of 0.5Hz, and even able to apply millions of pressure cycles.

Advantages of Pressure Cycle Testing

Pressure cycle testing enhances the product development process by simulating a products life in a shorter amount of time such that it can be evaluated and refined prior to being implemented. Some other benefits include:

- Time to Market: Early identification and resolution of potential issues through pressure cycle testing accelerate the product’s journey to the market.

- Enhanced Product Reliability: Uncovered weaknesses during testing improves reliability, reducing product failure risks and expensive recalls, thus conserving resources.

- Optimized Product Design: Pressure cycle testing yields invaluable data that can be used to refine product design, minimizing the need for subsequent changes and re-designs.

- Increased Customer Satisfaction: Products that align with customer expectations increase satisfaction and decrease the likelihood of lost business due to performance issues.

Real-World Applications

Products like valves, hydraulic systems, or fuel tanks that are subjected to pressure fluctuations in the field can benefit from pressure cycle testing. This controlled testing environment offers valuable insights into a product’s field performance, allowing potential issues to be addressed before market release.

Combined Loads Integrating Pressures for Authentic Simulation

Pressure cycle testing can be combined with other applied loads, such as temperature variations, tension, compression, bending, and harsh environments. This comprehensive approach empowers manufacturers to assess the cumulative impact of real-world conditions on product performance and can offer a more realistic simulation of field conditions.

Impulse Pressure Cycle Testing

Products subjected to sudden pressure fluctuations benefit from impulse pressure cycle testing. This method examines the effects of impulse loads on a product, pinpointing potential failure sites in hydraulic systems and aerospace components.

Overcoming Challenges

Despite challenges such as high equipment costs, lengthy testing times, and environmental factors, partnering with a trusted testing laboratory like Stress Aerospace and Defense can mitigate these obstacles. Our laboratory’s expertise, equipment, and facilities ensure precise and efficient pressure cycle testing, yielding high-quality results adapted to a product or component’s unique needs.

Wrapping Up

Pressure cycle testing is a vital tool for manufacturers and end-users aiming to enhance product performance, reliability, and safety. By replicating real-world conditions, stakeholders can preemptively tackle potential problems before a product launch, making informed decisions about design, materials, and production processes. From testing medical devices to aerospace components, pressure cycle testing is a fundamental component of a comprehensive product development and qualification program.