In mission-critical systems, structural failure is rarely isolated. It can cascade into functional breakdowns, missed objectives, and costly rework. Avoiding these outcomes requires testing under the conditions the system will actually face. However, in many development programs, structural testing is treated as a late-stage checkbox rather than a core element of the design process. The result? Missed failure modes, late-cycle redesigns, and delays that could have been avoided with a more strategic approach.

The most effective testing programs are tailored to the specific goals of a project, whether that means quick internal checks early in development or highly instrumented, third-party-verified validation for customer delivery. The key is to avoid overtesting, undertesting, or generating data that doesn’t answer the questions that matter.

Here, we share a practical approach to building a structural testing strategy grounded in real-world challenges. Drawing on five decades of experience between Stress Aerospace and Defense, LLC and Stress Engineering Services, Inc., we use a subsea drone example to show how thoughtful test selection, environmental simulation, and early planning contribute to a more effective structural testing strategy.

Structuring Tests Around Real-World Risk

Once structural testing goals are defined, the next step is selecting the methods and conditions that best reflect the system’s operational risks. For subsea applications, that might mean simulating deep-ocean pressure and cold, evaluating corrosion at dissimilar metal interfaces, or validating battery safety under environmental load. The following sections outline core structural test types and their relevance to a specific deployment scenario: subsea conditions.

Pressure Testing

Mission-critical systems must be validated under pressure conditions that accurately reflect their operational environment. For underwater environments, structural testing strategies typically include both hyperbaric and cyclic (fatigue) pressure testing. Hyperbaric testing applies static pressure to simulate maximum deployment depth, while cyclic testing mimics repeated ascents and descents. These conditions are essential for unmanned underwater vehicles (UUVs) operating in dynamic mission profiles.

Real-world benchmarks help define pressure targets. For example, the Challenger Deep, the ocean’s deepest known point, exerts up to 16,000 psi, while the average depth of the Pacific Ocean (~14,040 ft) results in approximately 6,300 psi. In addition to pressure magnitude, a robust test strategy considers ramp rates (i.e., ascent/descent speed) and dwell time. Fast ramp rates can introduce additional loading conditions that must be accounted for, and longer dwell times make it possible to observe water ingress, deformation, or seal failure under stable pressures.

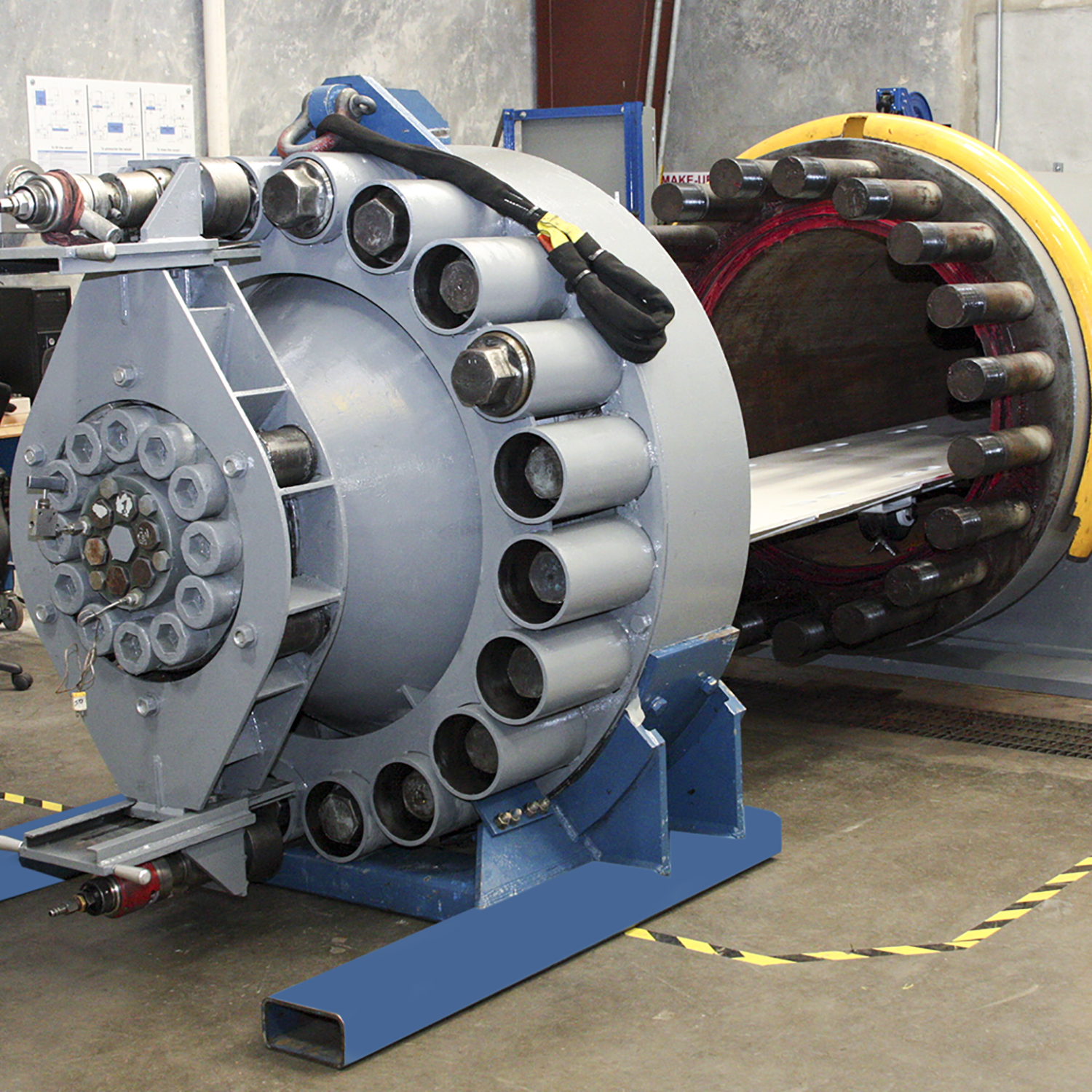

To gather meaningful data from pressure testing, engineers must ensure the test setup replicates real-world operating conditions as closely as possible without distorting the results. This starts with designing or selecting a pressure vessel that can apply uniform external pressure while maintaining the internal conditions the product would experience in the field. For subsea systems, that often means combining pressure with low temperatures, internal electronics under load, or fluid exposure, depending on the specific use case.

Layered testing conditions add complexity. For example, introducing cold water into a pressure vessel requires a chiller system, while monitoring performance under pressure may involve strain gauges, pressure sensors, embedded electronics, and subsea cameras for observation. Engineers must install these instruments carefully to prevent them from becoming failure points.

Another common pitfall is underbuilding the test fixture. The test rig must be more robust than the test article, or engineers risk damaging the setup before the product fails, rendering the data useless or inconclusive. When cyclic testing is involved, the system should also support high-speed pressure cycling, enabling accelerated life testing to reveal fatigue failures and long-term deformation.

Corrosion Testing of Metallic Materials

Corrosion is a significant threat to structural integrity in harsh environments. In subsea drone applications, seawater chemistry, dissolved gases, and microbial species can interact to accelerate material degradation. Corrosion risks must be considered early in the design process, especially when the structure includes dissimilar metals, new materials like 3D-printed alloys, or materials susceptible to environmentally assisted cracking. Subject matter experts can mitigate corrosion risks using informed material selection, cathodic protection systems, coating solutions, and other innovative technologies.

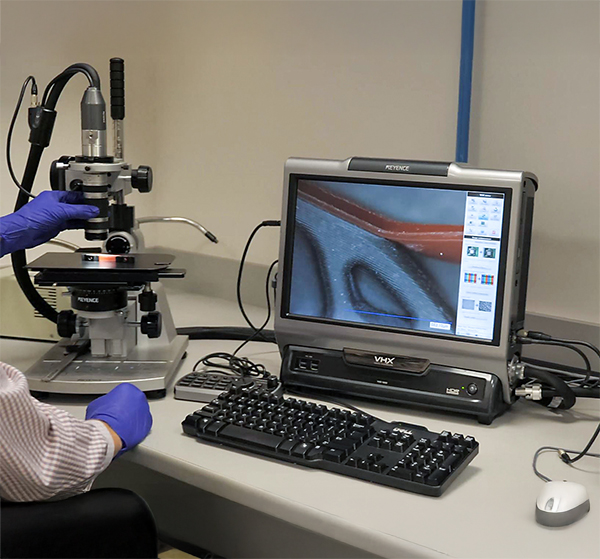

Effective corrosion testing goes beyond exposing a single alloy to a salt spray. Comprehensive validation may include full and partial immersion, high pressure exposure in autoclaves, wet-dry cycling, galvanic corrosion tests, and/or environmentally assisted cracking tests. These methods can simulate real-world ocean environments, including salinity, pH, temperature, and pressure profiles typical of the deployment zone. Proper simulation is especially important when qualifying systems with mixed-material joints or novel coatings. Beyond the material, coating, and welding procedure qualification testing, periodic corrosion tests can be a critical tool in ongoing quality assurance.

Compatibility Testing of Polymer Materials

Polymers (e.g., elastomers and thermoplastics) are often used in O-rings, seals, insulation, coatings, and housings, and their performance under extreme environmental conditions can be difficult to predict. Unlike metals, non-metallic materials can degrade through chain scission (i.e., bond breakdown), swelling, shrinkage, and softening at elevated pressures or over long-term exposure to seawater. Some elastomers can also experience explosive decompression upon sudden drops in pressure.

Material-specific testing is essential to qualify seals, coatings, and components for use at depth. Common protocols include chemical compatibility testing, where polymers are exposed to operational fluids (e.g., fuels or saltwater) to assess degradation, and pressure testing, which simulates how seals or coatings behave under compression during exposure. These tests help uncover failure modes that can lead to leaks, disbonding, and mechanical failure that may not be evident when tested under ambient conditions.

For use in mission-critical sealing applications, polymer components must be validated at both the material and system level. For example, a seal that passes a standard pressure test may still fail when subjected to repeated cycles or when interacting with other structural materials. This is especially true in multi-material joints, where differential thermal expansion or friction can introduce additional stress.

Test durations and protocols should reflect the specific demands of the application. In many cases, damage mechanics are time-dependent and may not activate in short-term tests. Since damage mechanisms may degrade at different rates over time, it’s important to test them across multiple exposure durations to develop accurate life prediction curves.

With multiple conditions at play, such as pressure, temperature, and chemical exposure, engineers benefit from an integrated testing approach. By combining these conditions into a single setup, they can observe how the material performs under realistic and potentially compounding effects. This level of realism is essential for ensuring that non-metallic components will perform reliably in subsea deployments, where failure modes often emerge from the intersection of multiple environmental and load factors, not from a single cause.

Thermal Testing

Thermal testing helps engineers understand how materials and assemblies respond to sustained heat, cold, and temperature fluctuations. For subsea drones, fluctuations can occur during descent, ascent, or from internal heat generation. Ocean temperature profiles serve as the foundation for designing meaningful tests. Near the surface (0–200 meters), temperatures range from 25–30°C (77–86°F) in tropical zones and -2 to 5°C (28–41°F) in polar regions. In the thermocline (200–1,000 meters), water cools rapidly to 5–15°C (41–59°F). At greater depths, temperatures stabilize around 0–4°C (32–39°F). These shifts can cause differential expansion, material brittleness, and fatigue in mixed-material assemblies.

To reflect these conditions in a lab setting, engineers may use constant low-temperature exposure, thermal cycling, or combined environmental tests that simulate both pressure and cold. The right approach depends on the system’s mission profile. Long-term deployments might call for extended exposure, while UUVs that travel up and down the water column benefit from rapid cycling or thermal shock tests that mimic extreme transitions.

For accurate results, thermal tests must be carefully controlled. Engineers need to manage temperature ramp rates, dwell times, and combined stress factors (e.g., pressure and moisture) while ensuring that sensors and monitoring systems don’t interfere with test integrity.

Battery Testing

Engineers must ensure that batteries used in subsea systems operate reliably under pressure, at low temperatures, and across extended mission durations. Therefore, test strategies should include a focused assessment of battery performance, degradation, and failure modes under real-world environmental stressors.

Battery testing is often integrated into pressure and thermal tests during full-system evaluations because batteries are typically housed within the vehicle. However, standalone battery testing is helpful for evaluating charge/discharge performance, thermal runaway behavior, insulation resistance, and dielectric withstand. These tests help identify how batteries perform under load, how they age with repeated cycling, and how they respond to conditions that could lead to thermal runaway.

Subsea deployment adds environmental challenges that can impact battery behavior in unique ways. Cold temperatures, for instance, reduce available capacity and can lead to lithium dendrite formation, while high pressure can deform enclosures or compromise seals, potentially resulting in short circuiting or isolation loss.

Depending on the mission profile, some programs simulate accelerated life cycles while others focus on specific thresholds. By performing environmental and electrical testing in tandem, engineers can uncover performance degradation, latent safety issues, and failure triggers that may not emerge under ambient conditions.

Other Critical Tests Outside the Structural Scope

It’s important to recognize that a comprehensive validation strategy includes non-structural and specialized testing too. Subsystems such as software, electronics, telecommunications, sonar, and guidance systems all require rigorous verification to ensure reliable operation under harsh conditions. In addition, specialized testing for electromagnetic interference (EMI), magnetic fields, and acoustic behavior may be necessary depending on the mission profile and onboard equipment.

These tests often run in parallel with structural validation or are integrated into full-system trials. Although not the focus here, their inclusion is essential for ensuring mission readiness, especially in defense or deep-ocean exploration contexts. A strong structural testing strategy provides the backbone for system integrity, but true operational success requires interdisciplinary coordination across all testing domains.