In October 2020, the USAF Rapid Sustainment Office’s Advanced Manufacturing Olympics posed a series of challenges aimed at pushing the boundaries of additive manufacturing and reverse engineering.

A team comprised of top engineering professionals from Stress Engineering Services, as well as the engineering software company nTopology, and the additive manufacturing firm, Origin was selected to compete in the Approval Sprints Technical Challenge along with other highly capable teams.

The Approval Sprints Challenge is focused on the C3175 family of hydraulic line clamps. The Air Force uses thousands of these hydraulic tube clamps in its fleet of aircraft.

The Challenge

The C3175-9J clamp, commonly used in the wheel well of F-16 aircraft, was selected as the specific component for this challenge. Service failures of these clamps have been attributed to the clamp’s prolonged exposure to harsh conditions such as vibration, chemical environments, and heat, which these parts endure over their lifetimes. The original design and documentation for the clamp dated back to the 1960s which made it difficult to find suppliers.

The challenge was not only to improve the performance and durability of the existing part but to showcase how a replacement part could be rapidly engineered, fabricated, and tested. SES sought to accomplish these goals by capitalizing on the capabilities of a rapid iterative design, analysis, qualification testing and an additive manufacturing process.

The objective of the Approval Sprints Technical Challenge was to push the boundaries of additive manufacturing and reverse engineering. The goal was not only to create a superior replacement for the C3175-9J clamp, but also to stimulate innovation in aerospace engineering, setting a new standard for future advancements in the field.

The Solution

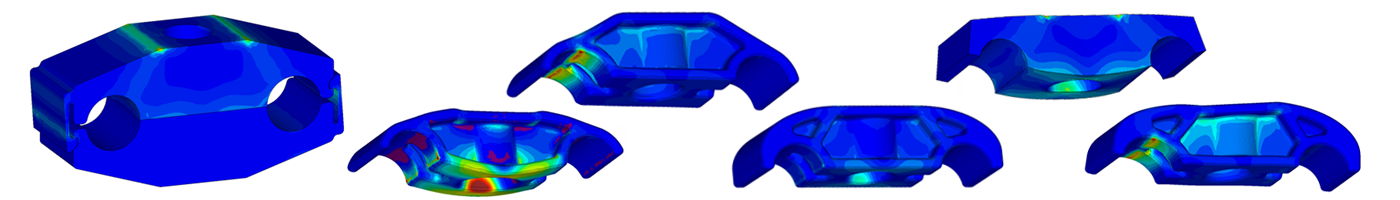

The SES/nTopology/Origin team adopted an innovative approach to address the issue with C3175-9J clamp. The strategy was anchored on rapid iteration of designs, analysis and testing. Over a span of only three weeks, the team executed more than 100 tests on 400 parts, developed over 30 separate designs, and carried out advanced analysis, full-scale testing, and final part production—all through 100% virtual collaboration.

Key achievements of the team were impressive and impactful. The redesigned tube clamp exhibited a load-bearing capacity double that of the original design. This increase in strength was achieved without adding weight to the part, a significant achievement in aerospace engineering where weight is a critical factor.

The team used Loctite 3955, a flame-retardant, chemically resistant material from Henkel. This material provided superior performance compared to the materials used in the original clamp. The new clamp was manufactured using the Origin One 3D printer, demonstrating the team’s adeptness in additive manufacturing.

This approach and these achievements not only solved the problem at hand but also pushed the boundaries of additive manufacturing and reverse engineering, setting a new benchmark in the industry.

Innovation and Impact

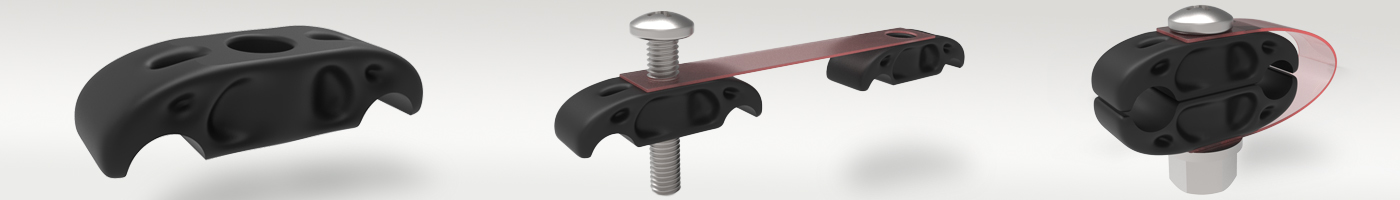

The SES/nTopology/Origin team introduced several innovative features in the redesigned C3175-9J clamp. One notable feature is the flexible elastomeric tether that connects the two clamp halves. Manufactured during the same process as the clamp components using the multi-material print capabilities of the Origin 3D printers, this tether facilitates installation and offers a significant improvement over the original design. It also reduces the number of individual parts from three to one.

Another forward-thinking feature of the new clamp design is the addition of serialization during the print process. This unique identifier for each assembly aids in inventory tracking and traceability, contributing to more efficient and reliable inventory management.

These innovations simplify the installation process by allowing one-handed installation, reducing the installation time by about half compared to the original clamp components. The implications for efficiency are substantial, as this design could potentially save hundreds of man-hours in aircraft maintenance.

The methodology developed by the SES/nTopology/Origin team during this project—designing, fabricating, and qualifying in rapid iterative cycles—has broader implications beyond the specific task of improving the C3175-9J clamp.

Broader Implications

This approach, which incorporated over 30 design iteration cycles and resulted in a highly optimized clamp design, can be applied to a multitude of parts across diverse industries. Whether it’s automotive parts, medical devices, or consumer products, this method offers a new way to rapidly invent, develop, and improve technologies.

In the aerospace sector, this methodology could lead to significant advancements in the design and production of aircraft components. The ability to rapidly prototype, test, and validate designs could accelerate the development of new technologies, relieve supply change issues, improve the reliability of existing parts, and potentially lead to substantial cost savings.

But the potential applications extend even further. Any industry that relies on the production of physical components could benefit from this rapid, iterative approach to design and manufacturing, unlocking new possibilities for innovation and efficiency.

Award Winning Innovation

At the conclusion of the three-week challenge, the team of Stress Engineering Services (SES), nTopology, and Origin emerged as first-place victors! Through rapid design iterations, comprehensive testing, and adept use of modern materials, the team developed a superior replacement for the C3175-9J clamp, demonstrating the power of collaboration and innovation in the process.